Jinzong Enterprise has been focusing on the production and research and development of water treatment equipment for over 10 years.

Today, we will introduce you to the relevant knowledge of reverse osmosis water treatment equipment. We hope that through this article, everyone can have a comprehensive understanding of reverse osmosis water treatment equipment.

一、 Preparation Principle

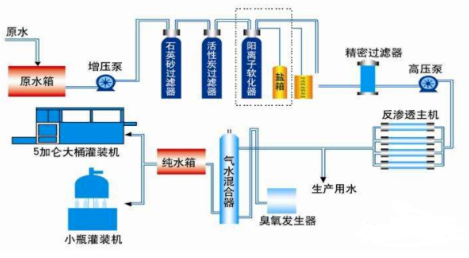

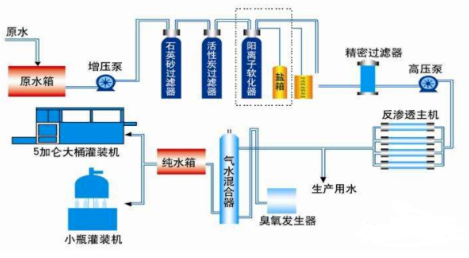

Reverse osmosis water treatment equipment usually consists of three parts: raw water pretreatment system, reverse osmosis purification system, and ultra purified post-treatment system. The main purpose of pre-treatment is to ensure that the raw water meets the inlet requirements of the reverse osmosis membrane separation component and the stable operation of the reverse osmosis purification system. Reverse osmosis membrane system is the most economical and efficient purification method for removing over 98% ions, organic matter, and 100% microorganisms (theoretically) in raw water at once. The ultra purification post-treatment system further removes trace ions, organic matter and other impurities remaining in reverse osmosis pure water through various integrated technologies to meet the final water quality indicators for different purposes.

二、 Working Principle

Reverse osmosis is the most precise membrane liquid separation technology, which applies operating pressure on the inlet (concentrated solution) side to overcome natural osmotic pressure. When the operating pressure higher than natural osmotic pressure is applied to the concentrated solution side, the flow direction of water molecules through natural permeation will be reversed, and the water molecules in the inlet (concentrated solution) will pass through the reverse osmosis membrane to become purified water on the dilute solution side; Reverse osmosis equipment can block all soluble salts and organic matter with a molecular weight greater than 100, but allows water molecules to pass through. The desalination rate of reverse osmosis composite membranes is generally greater than 98%. They are widely used in industrial pure water and electronic ultrapure water preparation, drinking pure water production, boiler feedwater and other processes. The use of reverse osmosis equipment before ion exchange can significantly reduce the discharge of operating water and wastewater.

三、 Introduction to Preprocessing System

Reverse osmosis water treatment systems generally include pre-treatment systems, reverse osmosis devices, post-treatment systems, cleaning systems, and electrical control systems. The pre-treatment system generally includes quartz sand filters, activated carbon filters, precision filters, etc. Its main function is to reduce the pollution index of raw water and other impurities such as residual chlorine, in order to meet the inlet requirements of reverse osmosis.

Detailed classification explanation of pre-treatment system:

1. Quartz sand filter Quartz sand filter mainly removes impurities such as suspended solids, colloids, sediment, clay, saprophytic plants, and particles in water. It can reduce the turbidity of water, achieve the purpose of water quality clarification, and protect the reverse osmosis membrane.

2. Activated carbon filter mainly utilizes a large number of hydroxyl (hydroxide) and hydroxyl functional groups on the surface of activated carbon to chemically adsorb various substances, remove odors, organic matter, colloids, iron, and residual chlorine in water, and reduce the color and turbidity of water, thereby reducing pollution to the reverse osmosis system.

3. The softener uses sodium ions on the ion exchange resin to exchange calcium and magnesium ions in water, reducing the hardness of the water, while regenerating the ion exchange resin with soft water salts. Soft water salt, also known as ion exchange resin regenerator.

4. Precision filter

The use of a 5-micron PP melt blown filter element is mainly to remove particles larger than 5 microns that have not been completely removed by the pre-treatment system, intercept the filter material lost in the previous three filtration procedures, and protect the RO membrane.

Whether the filter element can meet normal operating conditions will affect the normal working conditions of the membrane. Generally, the filter element is replaced every 3-4 months.

四、 Introduction to Reverse Osmosis System

The reverse osmosis system mainly consists of multi-stage high-pressure pumps, reverse osmosis membrane components, membrane shells (pressure vessels), brackets, etc. Its main function is to remove impurities from water and ensure that the effluent meets the requirements for use. The high-pressure pump pressurizes the outlet water of the security filter to the working pressure of RO, and then evenly distributes it to the pressure vessel. The water flow is separated by the reverse osmosis membrane and forms two water flows inside the pressure vessel. A portion of the incoming water passes through the membrane to form pure water, while the remaining inorganic salts and solid residues are retained and concentrated to form concentrated water, thereby achieving the separation of inorganic salts and water.

Pure water flows out from each pressure vessel equipped with reverse osmosis membrane components, converges through a flow meter, and then flows out of the equipment outlet into the pure water tank. Concentrated water flows out from the concentrated water outlet of the pressure vessel.

Reverse osmosis membrane desalination mechanism: The epidermis of the semi permeable membrane is covered with many extremely fine membrane pores, and the surface of the membrane selectively adsorbs a layer of water molecules. Salt solutes are repelled by the membrane, and ions with higher valence states are repelled further. Under the push of reverse osmosis pressure, water molecules around the membrane pores flow out pure water through the capillary action of the membrane to achieve desalination.

When the membrane pores are larger than the range of reverse osmosis membrane pores, the aqueous solution of salt will leak through the membrane, with more leakage of monovalent salt, followed by divalent salt, and less leakage of trivalent salt. The pore size of the RO membrane is less than 1.0nm, so the RO membrane can filter out one of the least bacteria, Pseudomonas aeruginosa (3000 × 10-10m); It can also filter out various viruses, such as influenza virus (800 × 10-10m) and meningitis virus (200 × 10-10m); It can even filter out heat sources (10-500 × 10-10m). The characteristics of using reverse osmosis method to prepare pure water are as follows: compact equipment structure and easy maintenance, small footprint, and high water production; Prepare pure water without phase change, with low energy consumption; At the same time, there is no discharge of acid, alkali and other wastewater, which is a new energy-saving and environmentally friendly equipment;

The ratio of wastewater to pure water in reverse osmosis systems is usually 3:1 for household small pure water machines, 1:1 for small industrial reverse osmosis systems, and 0.3:0.7 for large systems. If you want to reduce wastewater discharge, the cost will be relatively high, and the service life of reverse osmosis membranes will definitely be shortened.

This advanced membrane separation technology has been widely used in various fields.

五、 Reverse Osmosis System Maintenance

1. Carry out daily water quality testing and record equipment operating parameters, and promptly resolve any abnormalities found. Regularly check and record important parameters such as pure water conductivity, pressure at each point, and inlet and outlet water flow rate every day.

2. Regularly add regenerant to the salt box and set the regeneration time based on the actual situation and water production on site. Generally, it is added once every 3-4 days.

3. Replace the security filter element in a timely manner. (Usually replaced every 3-6 months)

4. Regularly wipe the machine and keep it clean.

5. Regularly check if there is any water leakage in the pipeline and promptly resolve it.

6. The normal water supply and power supply of the equipment should be ensured. In case of special circumstances such as power outage and water outage, the equipment needs to be rescheduled, especially the regeneration time after power outage needs to be reset.

It is prohibited for unrelated personnel to touch the buttons of the electronic control part and the valves of the pipeline part to prevent accidental operation that may cause the equipment to malfunction.

六、 Emergency Measures

When there is a power outage or damage to the main pump, membrane, and other components used to produce pure water that cannot produce pure water, the softened water valve can be opened to continue using the softened water to ensure the normal operation of the water equipment. This method needs to be based on the actual requirements of the water equipment.

1. When the water leakage of the equipment is severe, the water inlet switch of the equipment should be immediately turned off, and the power should be turned off, and the service provider should be notified to handle it.

2. During the water production process, if the pressure gauge after the membrane shows a pressure exceeding 1.5Mpa, the conductivity exceeds 15us/cm, or the produced water quality exceeds the standard range, consumables such as resin, membrane, and activated carbon should be replaced in a timely manner.

七、 Consumable Replacement Instructions

Due to the fact that consumables such as quartz sand, activated carbon, and softened resin are all granular objects, they can easily form porous structures after stacking, providing a growth environment for the long-term reproduction of fungi. At the same time, activated carbon and softened resin have a certain degree of saturation for adsorption. After long-term use, the filtration effect decreases. When the flushing regeneration cannot meet the pre-treatment effect, it can be replaced to ensure the inlet water quality of the reverse osmosis membrane.

When all conditions are met, the usage cycle of quartz sand is 10-24 months, activated carbon is 10-12 months, resin is 10-12 months, precision filter element is 3-6 months, and reverse osmosis membrane is about 12 months.

Resin regeneration cycle: Under normal conditions, the resin regeneration cycle is 1-3 days.

八、 Application Field

1.Electric power industry: boiler feedwater, cooling water dams;

2. Electronics industry: ultra pure water for semiconductor industry, integrated circuit cleaning water, formula water;

3. Food industry: formula water, production water;

4. Pharmaceutical industry: process water, formulation water, washing water, injection water, sterile water preparation;5. Beverage industry: formula water, production water, washing water;

6. Chemical industry: production water and wastewater treatment;

7. Drinking water engineering: preparation of ultrapure water and purification of drinking water;

8. Petrochemical industry: deep treatment of oilfield injection water and petrochemical wastewater;

9. Desalination of seawater: production and domestic water use in island areas, coastal water scarce areas, ships, seawater oil fields, etc;

10. Environmental protection field: Recycling precious metals and water from electroplating and rinsing water, achieving zero emissions.