A reactor is a common equipment in the chemical industry, used for chemical reactions, physical reactions, mixing, dissolution and other processes. It is widely used in chemical synthesis, petrochemicals, pharmaceutical manufacturing, food processing, cosmetics, new material production and other fields. Today, Jinzong Enterprise, with over 20 years of experience in reactor production and research and development, will provide a detailed explanation of the working principle and main components of the reactor.

1、 Working principle of reaction vessel

The basic working principle of a reactor is based on the mixing, heating, cooling, stirring and other operations of materials in a closed space, which promote various raw materials to undergo chemical reactions or physical changes. The core process can be summarized as follows:

1.Material loading and mixing: Firstly, the material to be processed is added to the reactor through a specific feeding port. The vessel is usually equipped with a stirring device, which can ensure uniform mixing of materials, enhance contact opportunities between reactants, and thereby improve reaction rate and efficiency.

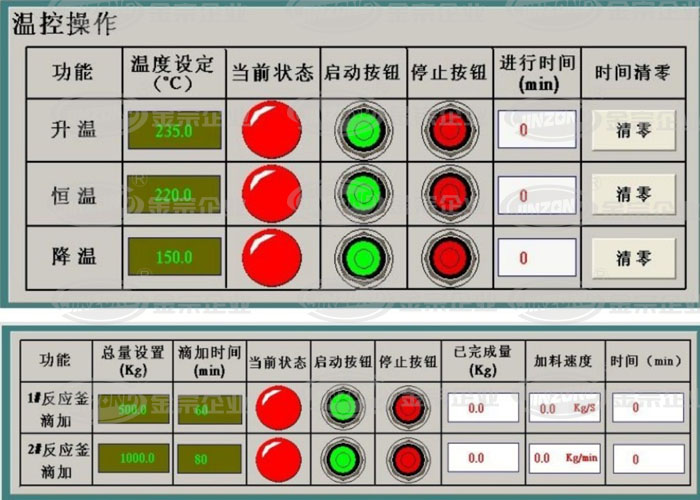

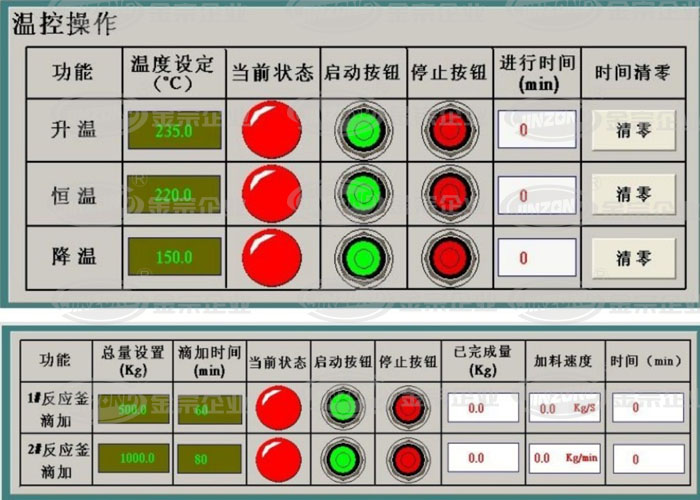

2.Temperature control: The reactor is equipped with an efficient heating and cooling system, which can accurately control the temperature inside the reactor. For exothermic reactions, excess heat can be absorbed through the cooling system; For endothermic reactions, necessary energy can be provided by heating elements. Temperature control is crucial for reaction rate and product quality.

3. Pressure management: The reactor has good sealing performance and can withstand pressure fluctuations within a certain range. Some reactions are more effective under high pressure, and the reactor needs to have sufficient pressure resistance and be equipped with a pressure monitoring and control system to ensure safe operation.

4. Reaction process monitoring: By installing various sensors on the reaction vessel, real-time monitoring of temperature, pressure, liquid level and other parameters inside the vessel can be carried out, and automatic adjustment or alarm signals can be sent out according to the set process conditions to ensure stable and controllable reaction process.

2、 The main components of the reaction vessel

A reactor typically consists of the following key components:

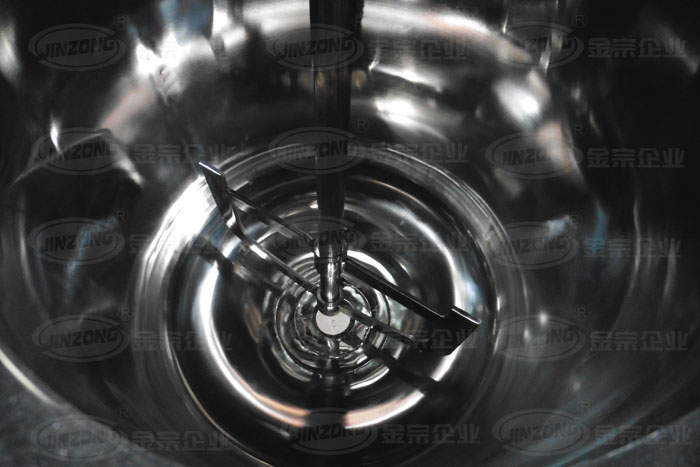

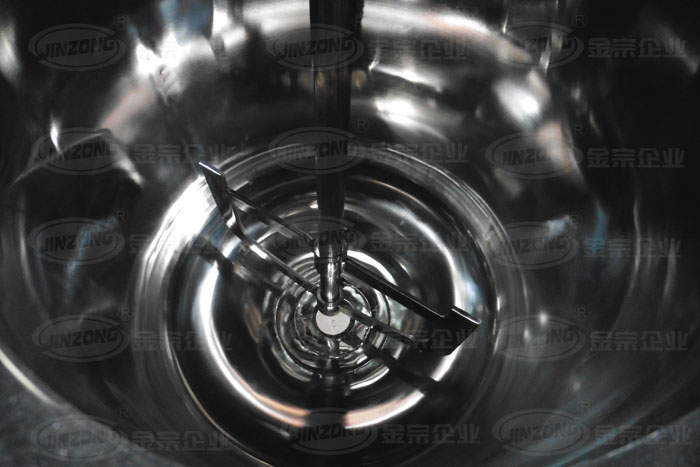

1.Vessel body: The vessel body is a space that accommodates reaction materials, and the materials used are mostly stainless steel, carbon steel, or other corrosion-resistant materials. The design should meet the corresponding pressure bearing capacity and temperature resistance requirements.

2. Stirring device: including stirring shaft, stirring blade, and driving device (such as motor reducer), used to fully mix the materials in the vessel and ensure uniform reaction.

3. Heating/cooling system: It can adopt forms such as jacket type, coil type, or electric heating to achieve precise control of the temperature inside the vessel, and is equipped with auxiliary equipment such as heat exchange medium circulation pump.

4. Pressure control system: including safety valve, pressure gauge, pressure relief valve, etc., to ensure that the pressure is always within the safe range during the reaction process.

5. Material inlet and outlet device: including feeding port, discharge port, sight glass, manhole, etc., to facilitate material addition and removal, as well as to facilitate inspection of the condition inside the vessel and cleaning and maintenance.

6. Measurement and control components: such as temperature sensors, pressure sensors, liquid level gauges, etc., collect real-time status data inside the reactor and transmit it to the control system.

In summary, as a precise and complex chemical unit operation equipment, the working principle of the reactor is aimed at optimizing the reaction environment to ensure the efficient and safe operation of the reaction process, and its various components work together to build a highly integrated and fully functional reaction system. Through rational design and precise operation, reaction vessels play a crucial role in modern industrial production.

Jinzong Enterprise was founded in 1999, specializing in the design and manufacturing of mechanical equipment, research and development of intelligent control systems, and engineering design and installation. The main products include synthesis reaction production lines, vacuum emulsification production lines, mixed extraction production lines, water treatment equipment, etc., which are widely used and mainly serve and apply in the automation production of fine chemicals, coatings, pharmaceuticals and food, automotive products, cosmetics, new energy materials, and other fields.

Jinzong owns several wholly-owned companies, including Guangdong Jinzong Machinery Co., Ltd., Jinzong Technology (Guangzhou) Co., Ltd., and Jinzong Intelligent Technology (Guangzhou) Co., Ltd. There is a design and marketing service center in Guangzhou, and two production factories have been built in the Zhaoqing National High tech Zone. They have the qualifications for special equipment pressure vessel manufacturing and pressure pipeline installation (GC2), and are a national high-tech enterprise and a provincial-level specialized and refined new enterprise. They have two provincial-level branded products, dozens of product patents, software copyrights, and provincial-level high-tech products. They have passed the national intellectual property standard certification, ISO9001-2015 international quality system certification, and EU CE certification, and have been awarded the title of "Guangdong Province Contract abiding and Creditworthy Enterprise" by the Guangdong Provincial Administration for Industry and Commerce for many years. They have users in more than 50 countries and regions around the world, and have been widely recognized and supported by more than 2000 small and large enterprises at home and abroad.

To do a good job, one must first sharpen their tools. Jinzong Enterprise upholds the concept of "quality is like gold, craftsmanship is the core", and provides advanced and automated production lines to manufacturing factories. Friends from home and abroad are welcome to visit and guide us!